Proceedings

of The World Avocado Congress III, 1995 pp. 323 - 330

EFFECT OF POSTHARVEST TREATMENTS AND STORAGE CONDITIONS ON AVOCADO FRUIT RIPENING AND QUALITY

Y. Fuchs and G. Zauberman E.I. Lederman

Department

of Postharvest EMBRAPA

Science

of Fresh Produce, Av. Gal. San Martin, 1371

ARO,

The Volcani Center, Bonji-50761-000 - Recife P.O.Box

6,

Bet

Dagan 50250, Pernambuco,

Israel Brazil

Abstract

Most of the common postharvest handling procedures

are of a physical nature and are applied before, during or after the cold

storage period. Variations in cold storage technologies, in combination with

changes in storage atmosphere such as controlled atmosphere (CA) and modified atmosphere

(MA), are reviewed. Some attempts to reduce chilling injuries are discussed.

Physiological aspects of avocado ripening and quality, including involvement of

some related enzymatic activities, are considered.

Key index words

Avocado, postharvest, storage,

ripening, quality, chilling injury, ACC-oxidase.

1. Introduction

The main objective of

postharvest treatments of avocado fruit is to present good quality fruit to

consumers in markets which may be far away from the growing regions. However,

there is no complete and objective definition of quality for avocado. Quality

is a matter of location: The US standards for Floridian avocado are different

from the "California Food and Agricultural Code" for avocado, and the

Israeli standards are different from both of the American ones. Only recently

was an OECD international standard established. If we look at it as Wills et

al. (1981) did, "...quality depends on the position of the recipient in

the distribution chain." we shall attempt to address quality criteria from

the consumers' outlook, in which the general appearance (including size, color,

shape, firmness and absence of defects) is usually the most important quality

factor for most people. The texture, or firmness, is the next most important

factor, after which come taste and flavor and, last, the nutritional value of

the fruit. Consumers on the export markets in Europe, Japan or Canada buy

avocado more for aesthetic reasons than for the calories or vitamins it

contains. In this review-lecture we shall try to discuss mainly subjects which

were proposed for presentation by the participants this congress, assuming that

people have suggested the most important issues which are now on the agenda for

avocado postharvest studies.

2. Fruit maturity determination

The moment of harvest is the

beginning of the postharvest life of the avocado fruit, but before that a

decision has to be made about the readiness, or maturity, of the fruit for

harvest. Because of the special nature of the avocado fruit, we are used to calling

"maturation" - the processes occurring up to harvest and

"ripening" - the syndrome of events taking place in the fruit after

harvest, of which softening is the most obvious one. The great natural

variability of avocado fruit is a serious problem which was addressed in

several presentations at this congress.

The question when to start harvesting avocado fruit

is a commercial one. The desire to come to the markets with fruit as early as

possible has generated much research to determine the right maturity for

harvest for the different varieties. Oil content is regarded as a most

important factor in the taste of avocado fruit. To date, maturity determination

for commercial purposes employs destructive methods which are based on either

oil content or dry matter, which are highly correlated. The ideal situation

would be to determine fruit maturity nondestructively, on the tree, before

harvest.

In the early 1980s we

developed, together with Karl Norris from Beltsville, Maryland, a

nondestructive method for oil content determination using near infrared (NIR)

technology with a one-of-a-kind set-up which he had in his laboratory. This

method was not published. An attempt by a company in the USA to produce a

commercial portable instrument based on the same NIR technology, failed. Two

presentations at this meeting which described new nondestructive approaches to

determine ripening state (and maybe even maturity), join attempts using other

methods which were discussed and then published following a workshop held in 1993

(Brown and Sarig, 1994).

3. Postharvest handling

The harvesting, handling and

transportation to the packinghouse and all operations conducted there, must be

done carefully, in order not to cause mechanical damage. Any injuries would later

accelerate ripening and spoil the appearance of the peel with blemishes and

browning phenomena during and after storage. When we pull or snap a fruit

instead of clipping, we wound it; likewise, rough handling may result in

browning. Some fruits are more susceptible to handling blemishes than others

and it is possible that preharvest factors are involved; however, that subject

is not within the scope of this paper. Most postharvest treatments are done in

order to delay the onset of ripening and to slow down the natural processes of

the physiological deterioration of the fruit.

3.1. Prestorage treatments

Waxing may be regarded as a

cosmetic treatment, as it imparts glossiness, but it has also pronounced

physiological effects, especially on the internal atmosphere and weight loss of

the fruit (Durand et al., 1984). A gain of 1 or 2 days of shelf-life may be

achieved, but in some cases at the expense of development of more fruit rots.

Similar results (with even longer shelf-life) were reported, in a poster presentation

at this congress for N,O-carboximethyl chitosan.

The use of methyl bromide is being phased out and low

temperatures are being introduced for disinfestation purposes. Postharvest

fungicide applications were reported in the past, but they are not used

commercially in Israel and we do not have any information about the use of

fungicides as a routine commercial postharvest treatment in other countries.

However, in reports at this meeting, from New Zealand, Australia and Israel,

prochloraz was used experimentally.

Acclimation is being used successfully in South

Africa, where it is called "temperature management" the fruit

temperature being reduced gradually (Vorster et al.,1990).

Heat-shock prestorage treatments between 37 and 46ºC

were reported at this congress in two presentations. However, they are not yet

ready for commercial application.

In our Department (Pesis et

al., 1994), low-oxygen atmosphere prestorage treatments (3% oxygen and 97%

nitrogen) for 24 h reduced

chilling-injury symptoms in 'Fuerte' avocado fruit after 3 weeks of storage at

2ºC. Also softening was slowed down by this treatment. However, this treatment

is not yet employed commercially.

Acetaldehyde vapor (5000

μl.l-1 for 18 h) pretreatment of

'Fuerte' avocado fruit was reported at this meeting, but is not yet being used

commercially.

In our laboratory, methyl jasmonate pretreatment

reduced chilling injuries in 'Fuerte' avocado fruit, but there is still much to

learn before it can be applied.

Hydrocooling was tested as a result of cooling the

fruit as rapidly as possible to the optimal storage temperature, but after 25

min on the packing line the net gain, in cooling, was found to be inefficient

for the method to be economical.

Calcium infiltration has been known for many years to

slow down softening in avocado, but it is not being used commercially.

Carbon dioxide shock pretreatment (25% in air, for 3

days) was found-to be a promising treatment in South Africa (Bower-et al.,

1989) and also in Israel to chilling injury development.

In a recent publication (Prusky et al., 1995) and at

this congress, it was suggested that a Postharvest dip or spray of avocado

fruit with the antioxidant butylated hydroxyanisol (BHA) might reduce

Postharvest decay in avocado by modulating the natural fruit resistance. This treatment has reached the

semicommercial experiment stage, but is not being used yet.

3.2 Storage conditions

Temperature is no doubt the single most influential

factor in fruit storage. All biological

processes are controlled by temperature and thus fruit quality and ripening are

strongly affected by storage temperature.

However, it should be remembered that we cannot “cure” bad quality fruit

with Postharvest treatments. The issue

is to slow down the natural deterioration by lowering the temperature of the

fruit as much as possible without damaging it.

Avocado, being of subtropical origin, should not be cooled to even close

to its freezing point, as it suffers chilling injury at temperatures much above

the freezing point. All this makes the

art of maintaining the quality of avocado fruit, during and after cold storage

a difficult task. To demonstrate this

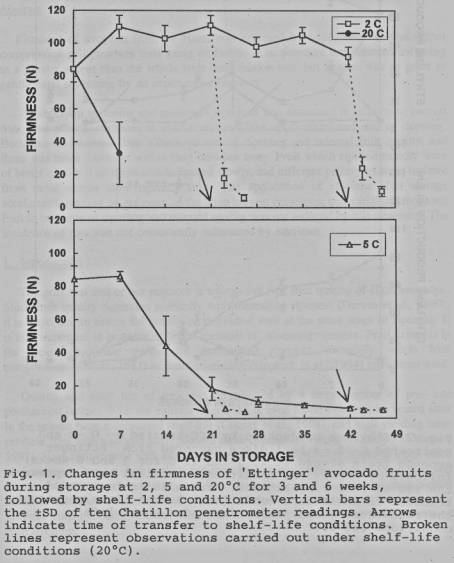

in quite a simple way, we present data which were generated last year during

cold storage of ‘Ettinger’ fruit, harvested at the end of October – which is

about mid-season for harvesting this variety in Israel. Fruits were stored at 2, 5, and 22°C, those

from 2 and 5°C were transferred after 3 weeks to 20°C for ripening. Fruit samples were taken weekly for

determination of firmness using a Chatillon pressure tester. We know from experience that we can feel

manually any change in firmness, only when less than 40 N is needed to

penetrate the fruit; and the fruit is ready to eat when less than 15 N is

needed for penetration. As shown in

Figure 1, at 5°C the fruit became softer already after 2 weeks of storage,

while the fruit stored at 2°C remained firm for 6 weeks. However, after 3 weeks at 2°C we started to

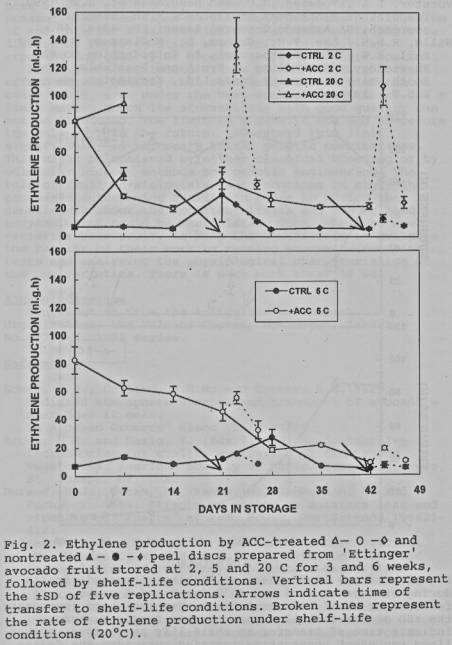

observe chilling-injury symptoms, while none developed at 5°C. From the same fruits on which firmness was

determined, peel discs were prepared (10 mm in diameter and ~2 mm thick). Then their ACC-oxidase activity was assayed

by measuring ethylene production after incubation with or without the addition

of a saturating concentration of ACC.

The avocado peel has a surplus of ACC-oxidase activity on the day of

harvest (Fig. 2), which decreases during storage. At a chilling-inducing temperature of 2°C, the removal of fruit

to shelf-life conditions (20°C), for ripening, significantly enhanced

ACC-oxidase activity after 3 and 6 weeks at storage whereas at 5°C this

activity was hardly noticeable. Similar

patterns were found in our studies with fruit of the ‘Fuerte’ and ‘Reed’

varieties. It appears that, as in

apples (Lelievre et al., 1995) enhanced ACC-oxidase activity in avocado is

related to chilling injury development.

Chilling symptoms in avocado may appear in different

ways: surface or internal browning, surface pitting, failure to ripen,

increased susceptibility to microorganism attack, and pulp spots are found in

South Africa (but generally not in other places) as well as chlorotic

appearance of the peel, as is found with cold- stored Israeli 'Ettinger'. Most

of the pretreatments mentioned above are supposed to maintain quality by

enabling fruit storage at low temperatures which would otherwise - without the

pretreatment - cause chilling injury.

3.3. Atmosphere

composition

All methods and combinations

of atmosphere modification which work with apples were tried also with avocado,

but so far they have not succeeded as well as with apples and there is no

large-scale commercial use of these methods with avocado. There is a lot to

study on the local level, in each growing region, before controlled atmosphere

(CA) and modified atmosphere (MA) can be used commercially on a large scale.

We all know that ethylene is involved in avocado

ripening and thus when we are interested in delaying ripening during cold

storage, we have to eliminate the ethylene in the storage atmosphere. This is important

for normal atmosphere storage as well as for CA and MA. The presence of

ethylene during cold storage would cause pulp discoloration and shortening of

shelf-life after removal from cold storage. Ethylene can be removed by

ventilation, absorption by potassium permanganate, or by scrubbers or other

technologies in CA storage. However, ethylene can help us to obtain a better

quality fruit for the consumer when it is used as a ripening agent. This has

been done in Israel for more than 25 years, mostly for big customers who insist

on having all the fruit ready for consumption on a certain day. We introduced

this idea to some of our customers in Europe already in the 1970s in order to

develop the "ready to eat" line of avocado in some of the chain

stores. In addition to achieving uniform and controlled softening, the fruit

might escape rots, as the accelerated ripening leaves less time for pathogenic

fungi to develop and the final result is a better quality fruit for the

consumer.

4. Concluding remarks

It should not be forgotten that all the common

knowledge of today is based on a lot of research work which has been done in

the past. The bulk of the research on enzymes in avocado fruit was done mainly

with regard to fruit ripening and quality. We use various enzymatic assays as

markers in many of our studies. The basic role of cellulase and pectic enzymes

in avocado softening has been studied all the way to the gene level. In a

presentation from Japan at this congress, the purification of and role for β-galactosidase

in avocado softening were discussed. There is still a lot to learn about the

ripening and quality of avocado fruit, and their control.

Postharvest treatments of the fruit have an important

effect on its quality, but we should bear in mind that every fruit, even under

the best storage conditions, has a limit beyond which its storeability with

good quality cannot be stretched. The limit is a genetic one and therefore the

only way, in the future, to extend this limit significantly is to create better

genetic combinations. This might be achieved by either classical breeding or by

molecular biology methods and genetic engineering. The role of fruit

physiologists is to continue to study the processes determining quality in

order to advise the geneticists about the important traits and the related

enzymes which could be manipulated. Then, when the new varieties bear fruit, to

help the geneticists to evaluate the results of their work by running storage

simulation tests and analyzing the physiological characteristics of the new

varieties. There is much work ahead of us.

Acknowledgements

Contribution from the

Agricultural Research Organization, the Volcani Center, Bet Dagan, Israel. No. 1776-E, 1995 series.

References

Bower, J.P., Cutting, J.G.M.

and Truter, A.B. 1989. Modified atmosphere storage and transport of avocado

what does it mean. SA Avocado Growers' Assoc Yb 12:17-20

Brown, G.K. and Sarig, Y.

(Eds.) 1994. Nondestructive technologies for quality evaluation of fruits and

vegetables. American Society of Agricultural Engineers, St. Joseph, MI, USA.

Durand, B.J., Orcan, L.,

Yanko, U., Zauberman, G. and Fuchs, Y. 1984. Effects of waxing on moisture loss

and ripening of 'Fuerte' avocado fruit. HortScience 19:421- 422.

Lelievre, J.-M., Tichit, L.,

Fillion, L., Larrigaudiere, M., Vendrell, M. and Pech, J.-C. 1995. Cold-induced

accumulation of 1-aminocyclopropane-l-carboxylate oxidase protein in Granny

Smith apples. Postharvest Biol. Technol. 5:11-17.

Pesis, E., Marinansky, R.,

Zauberman, G. and Fuchs, Y., 1994. Prestorage low-oxygen atmosphere treatment reduces chilling injury

symptoms in 'Fuerte' avocado fruit. HortScience 29:1042-1046.

Prusky, D., Ohr, H.D., Grech,

N., Campbell, S., Kobiler, I., Zauberman, G. and Fuchs, Y. 1995. Plant Dis. 79:797-800.

Vorster, L.L., Toerien, J.C.

and Bezuidenhout, J.J. 1990. Temperature management of avocados - an integrated

approach. SA Avocado Growers' Assoc. Yb. 13:43-46.

Wills, R.H.H., Lee, T.H., Graham,

D., McGlasson, W.B. and Hall, E.G. 1981. Postharvest, An Introduction to the

Physiology and Handling of Fruit and Vegetables, New South Wales University

Press Ltd., Kensington, N.S.W., Australia.