Proceedings of The World Avocado Congress III, 1995 pp. 335 - 339

SENSITIVITY OF AVOCADO FRUIT TO ETHYLENE

P.J. Hofman, R.L. McLauchlan and L.G. Smith

Horticulture

Postharvest Group

Department

of Primary Industries Queensland

19 Hercules Street, Hamilton, 4007

Australia

Abstract

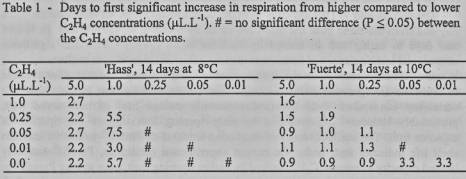

The respiration of

individual 'Hass' and 'Fuerte' fruit was monitored during storage at 8ºC and

10ºC respectively for 14 days, under a continuous flow of humidified air containing

ethylene (C2H4)

at 0, 0.01, 0.05,

0.25, 1.0 and 5.0 μL.L-1. Respiration rates of 'Fuerte' fruit

under 0.01 μL.L-1 C2H4 were significantly higher

than the controls after 3.3 days of storage, but for 'Hass' fruit respiration rates

did not become significantly higher until under 1.0 μL.L-1 for

5.7 days.

In another experiment,

'Hass' fruit were held in the presence of 0, 35, 70, 140, 280 or 1000 g of

Purafil® (C2H4

absorbent) at

20ºC. Increasing amounts of Purafil® consistently reduced the maximum

concentration of

C2H4 detected in the storage containers. Days from harvest to maximum

detected C2H4

production rate

(MDEPR) in bulk samples was increased from 8.1 to an average of 11.1 days by

the presence of Purafil®, but increasing amounts of Purafil® had no further

effect. Fruit stored individually in ventilated containers in the absence of

Purafil® reached MDEPR on average at 13.8 days.

These results indicate that

stimulation of ripening by C2H4 evolution from earlier- ripening fruit may be

important in hastening ripening of fruit stored in bulk. Ethylene removal in

storage may offer some advantage, but concentrations may need to be reduced to

0.05 μL.L-1 or lower to obtain

significant benefit, especially for 'Fuerte'. However, storage of only those

fruit with similar storage capacity is likely to be of greater benefit. A

knowledge of production factors contributing to poor storage life is required.

1. Introduction

Avocado marketing within

Australia generally requires transport by road under cold storage temperatures

(ideally 7-10ºC) for 3-7 days, and sea freight to export markets will require

3-5 weeks storage life. Control of ripening is essential to successful

marketing under these conditions.

Ethylene plays an important

role in fruit ripening. Fruit sensitivity to C2H4 and the presence of C2H4

during storage

is generally undesirable, and reduction of C2H4 in commercial storage of

several fruits is practiced. Since avocado fruit are sensitive to C2H4 (Zauberman and Fuchs, 1973;

Adato and Gazit, 1974), their storage should benefit by control of C2H4

concentrations.

This paper describes some of the responses of avocado fruit to storage under

various conditions in relation to C2H4.

2. Materials and Methods

2.1 Experiment I

'Hass' avocado fruit were

obtained by road freight from south east Queensland, and in another experiment

'Fuerte' fruit from north Queensland by airfreight. Fruit were placed in

individual, sealed containers and ventilated with air (93-95% RH) containing 0,

0.01, 0.05, 0.25, 1.0 and 5.0 μL.L-1 C2H4, at a flow rate of 25-40

mL.min-1. Effluent gas streams from each container were connected

via a rotary gas sampling unit to an infra-red gas analyser (Horiba PIR-2000)

for carbon dioxide (CO2) analysis. Seven fruit were used for each C2H4 concentration. 'Hass' fruit

were stored at 8ºC and 'Fuerte' fruit at 10ºC, to represent typical

temperatures observed during commercial refrigerated road transport. Fruit were

removed at 14 days, and held for a further 6 days at 20ºC to ripen.

Skin colour was measured

using a Hunter Labscan 6000 0/45º spectrocolorimeter fitted with a 25 mm

orifice, D65 illuminant, and 10º observer. Fruit firmness was quantified using

an Instron Universal Testing Machine model 1122, fitted with a 12 mm

hemispherical probe (probe penetration 2 mm at 20 mm.min-1).

2.2 Experiment 2

'Hass' avocado fruit were

harvested from south east Queensland and dipped in 0.55 mL.L-1 prochloraz for 30 sec. The following day, 42 fruit were

individually weighed and sealed in separate 1.4 L respiration chambers at 20ºC,

each ventilated with 90-160 mL.min-1 C2H4-free, humidified (93% RH)

air. In addition, samples of 20 fruit were sealed in each of 6 ventilated 30 L

plastic containers, each receiving about 300 mL.min-1 C2H4-free, humidified air. Purafil® (0, 35, 70, 140, 280

and 1 000 g) was placed in each of the containers to absorb fruit-produced C2H4. The effluent gas from each

container was connected via the 50 channel rotary gas sampling unit to a

Shimadzu gas chromatograph for C2H4 analysis. The days to C2H4 peak, the maximum detected

concentration in each container, and the % dry matter (DM) of fruit at eating

soft were determined.

3. Results

3.1 Experiment I

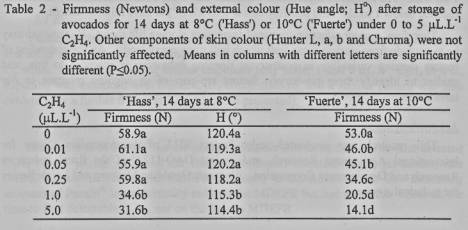

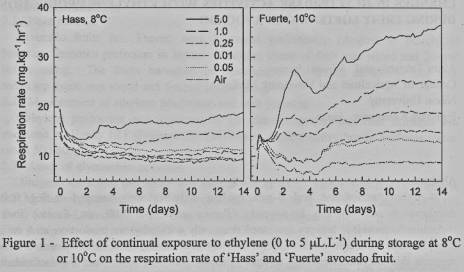

'Fuerte' fruit showed enhanced

ripening at 10ºC (significantly higher respiration rate, and softer fruit)

under all C2H4

treatments

compared to the control (figure 1; tables 1 and 2), while 'Hass' fruit showed

similar responses only under 1 and 5 μL.L-1 C2H4 at 8ºC. Ripening was enhanced with higher C2H4 concentrations, and a

similar pattern was also evident after a further 6 days at 22ºC (data not

presented).

3.2 Experiment 2

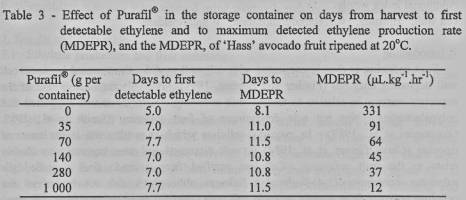

The presence of Purafil® in

the storage container increased the time to first detected C2H4 (>

0.1 μL.kg-1.hr-1 ) and the time to maximum

detectable C2H4

production rate

(MDEPR), and decreased the MDEPR compared to the control (table 3). Increasing

amounts of Purafil® logarithmically reduced the MDEPR but had no further effect

on the time to first detectable C2H4, nor on the time to MDEPR.

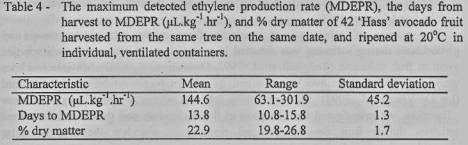

Fruit from the

same harvest, when stored individually, on average reached MDEPR after 13.8

days (table 4), compared to 8.1 days for the 20 fruit stored together in the 30

L container (table 3, 0 Purafil®).

There was also considerable variation in MDEPR, days to MDEPR, and % DM between

individual fruit (table 4). No significant correlation was observed between

days to MDEPR and % DM. Similar results, indicating more rapid ripening of

fruit stored together compared to fruit stored in isolation, were obtained with

later harvests (data not presented).

4. Discussion

These results confirm avocado

sensitivity to C2H4, even at relatively low storage temperatures. The significance of these results depends on storage time, but

the enhancement of ripening noted under exposure to 1.0 and 0.01 μL.L-1 C2H4 for 'Hass' and 'Fuerte" respectively is likely to be significant in

long-term commercial storage. The apparently greater sensitivity of 'Fuerte' in

this experiment would have been slightly influenced by the higher storage

temperature used for 'Fuerte'. Possible differences in maturity between the two

cultivars may also have had an effect. However the magnitude of the difference

suggests a cultivar difference in sensitivity. The thicker skin of 'Hass' may

contribute to a reduced sensitivity to C2H4, mediated through increased

diffusive resistance to C2H4 (Banks et al., 1993).

The variation in % DM and

days to MDEPR in avocado fruit harvested on the same day and from the same

trees has also been noted by Smith et al. (1992), and in % DM and days to

eating soft in mango by Hofman et al. (1995). This has significant commercial

implications, and an attempt to reduce this variation to give uniform ripening

is one of the main reasons for the development of C2H4 ripening procedures for

avocado in Australia (Ledger and Barker, 1994). The present results also

indicate that this variability can reduce shelf life (and potentially storage

life) of bulk-stored fruit, presumably because C2H4 produced by early-ripening

fruit triggers the ripening of adjacent fruit. The ineffectiveness of

increasing amounts of Purafil®

to further increase shelf life indicates that, under the current experimental

conditions, Purafil® has only limited capacity to

remove C2H4 evolved by earlier ripening fruit, even at 1 kg Purafil® to 7 kg fruit. The results of

experiment 1 indicate that C2H4 concentrations may need to be

reduced below 1 μL.L-1 (and

possibly below 0.05 μL.L-l ) to have

reliable benefit.

Therefore, a more effective

means of increasing storage life than C2H4 removal may be to exclude

from storage those fruit which will ripen prematurely. An understanding of

factors causing variability in postharvest ripening behaviour is essential to

this, and studies to identify these pre-harvest factors are part of an ongoing

program in our laboratories.

Acknowledgments

This research was conducted

under Project 9313 of the Australian Centre for International Agricultural Research,

and project DAQ-I 17A of the Rural Industries Research and Development

Corporation. We thank Geraldine Meiburg and Leigh Barker for technical support.

References

Adato, I., and Gazit. S.,

1974. Postharvest response of avocado fruits of different maturity to delayed

ethylene treatments. Plant Physiol. 53:899-902.

Banks, N.H., Cleland, D.J.,

Yearsley, C.W., and Kingsley, A.M., 1993. Internal atmosphere composition - a

key concept in responses of fruit and vegetables to modified atmospheres. Proc.

Australasian Postharv. Conf. 1993: 137-143.

Hofman, P.J., Smith, L.G.,

Holmes, R., Campbell, T., and Meiburg, G., 1995. Mango fruit quality at harvest

is affected by production conditions. Proc. Aust. Mango 2000 Production

Workshop (In Press).

Ledger, S.N., and Barker,

L.R., 1994. Ripeness indicators in Hass avocados. Internal Report, Horticulture

Postharvest Group, DPI, Queensland.

Smith, L.G., Jordan, R.A.,

Hofman, P.J., Jobin-Decor, M., Zauberman, G., and Ledger, S.N., 1992. Long term

storage of avocados. Proc. Aust. Avocado Growers' Fed. Conf. 'Management into

the Future'.

Zauberman, G., and Fuchs Y.,

1973. Ripening processes in avocado stored in ethylene atmosphere in cold

storage. J. Amer. Soc. Hort. Sci. 98:477-480.