Proceedings of The World Avocado Congress III, 1995 pp. 370 - 373

FRESH AVOCADO PULP (PERSEA AMERICANA MILL.) STORED UNDER

MODIFIED ATMOSPHERE USING VACUUM, CO2 AND N2 IN LOW DENSITY POLYETHYLENE BAGS.

José A.

Olaeta. and Pedro Undurraga

Facultad de

Agronomía

Universidad

Católica de Valparaíso - Chile

Proyecto

Fondef AI-04

Keywords: Gamma IV, gas storage,

processing, polyethylene bags, pulp.

Abstract

Avocado cultivars Hass,

Bacon, Fuerte and Gwen, grown in the Quillota Valley, Chile, during 1994

season, were harvested at two maturity levels, measured by oil content. The

fruit was ripened in a chamber at 13-15 ºC until 2-3 kg pressionometer value (2

cm2 end) was reached, peeled,

sliced or smoothed and stored at 1 ± 0.1 ºC in low density polyethylene bags, at

40% vacuum; 100%

CO2; 80% CO2 - 20% N2 and 100% N2 atmosphere during 7, 14, 21, 28, 35 and 42 days. The cultivar and the

maturity level had important effect in the quality of fresh pulp maintained in

cold storage. Gwen cultivar had the best quality of the product 80% CO2 - 20% N2 was the best gas combination to maintain a good quality of avocado pulp

in storage.

1. Introduction

Avocado flesh is normally

consumed as fresh product in paste, halves or slices. In Chile the avocado

products became more consumed, especially in restaurants, cafeterias and fast

food stores. The supply of avocado products ready to use is very important, in

order to save labor hand and costs.

The avocado flesh quality is

mainly affected by the cultivar and the maturity level of the fruit (Hatton and

Campbell 1959, Olaeta and Undurraga 1995). Modified atmosphere, using vacuum, CO2 and N2 in low density polyethylene bags, can reduce the enzymatic browning and

microbial spoilage, maintaining the quality of avocado flesh pulp (Arpaia 1988;

Olaeta et. al. 1995.). The effect of cultivar and the maturity level on the

quality of fresh avocado pulp stored under modified atmosphere using vacuum, CO2 and N2 is reported in this paper.

2. Material and methods

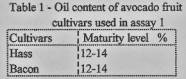

The avocado cultivars

Fuerte, Hass, Bacon, Negra de la Cruz, Edranol and Gwen, grown in the Quillota

Valley, Chile during the 1993 - 1994 season were harvested using oil content

(tables 1 and 3). The fruit of the cultivars named above, were ripened in a

chamber at 13 - 15 °C until 2 - 3 k firmness (2.0 cm2, end) was reached. Each cultivar fruit was hand

peeled, and half of it was cut in slices. The rest of the fruit was blended and

reduced to smooth uniform pulp. The flesh color of each cultivar was measured

using Minolta C-200 colorimeter and the results expressed in L, a, b., values.

The pulp was treated with 0,2% ascorbic acid and 0,6% citric acid mixture

incorporated in the pulp, and the slices were immersed in a 0,3% ascorbic acid

and 0,4% citric acid solution during 5 min. to prevent browning (Olaeta, J.A.

and Rojas C. 1987).

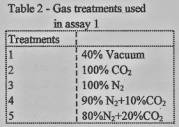

2.1. Assay I: gas

treatments.

Bacon and Hass cultivars

samples were packed in 300g low density polyethylene bags, treated with vacuum,

CO2 and N2 (table 2), and stored at 1 ± 0.1

°C during 7, 14, 21, 28 and 35 days.

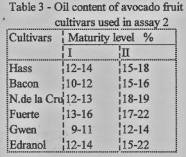

2.2. Assay II: maturity

levels.

Bacon, Hass, Edranol,

Fuerte, Negra de la Cruz and Gwen cultivars samples, in each maturity level

(table 3), were packed in 300 g low density polyethylene bags, treated with 80% CO2 - 20% N2 mixture, and stored at 1± 0.1

°C during 7, 14, 21, 28 and 35 days.

After each storage period,

in both assays, color (Minolta C-200), pH and acidity were measured and samples

were subjected to a sensory evaluation panel of 10 members to judge flavor,

color and general desirability using hedonic scale 1= Extremely undesirable and

7= Extremely desirable.

3. Results

3.1. Assay I: gas

treatments.

In both cultivars, better

quality products during 35 days storage period were reached using 80% N2 - 20% CO2 and 90% N2 - 10% CO2 gas mixtures, in slices and

pulp, Hass cultivar also reach good quality products with only 40% Vacuum

treatment. After that period of time the samples became dark. During 35 days

storage period, samples packed in 100% CO2 gas treatment, increased the

acidity and developed an effervescent taste.

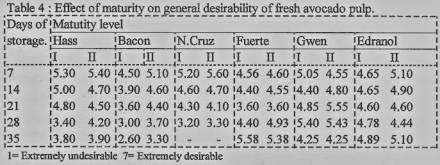

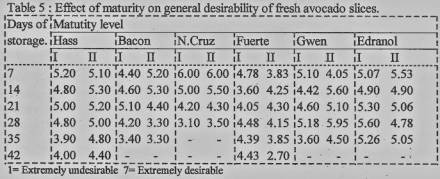

3.2. Assay II: maturity

levels.

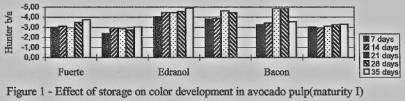

The original color of

cultivars Gwen, Edranol and Hass remained during 35 days of storage. Fuerte, N.

de la Cruz and Bacon cultivars became darker after 21 days of storage. The best

quality color in all storage periods, was reached by Gwen and Hass cultivars

(fig 1). In Bacon cultivar, better general desirability was found in avocado

pulp using lower maturity level but in general, the maturity level did not

affect the general desirability in the rest of the cultivars, both in slices or

pulp (tables 4 and 5). After 35 days of storage, pulp of the Fuerte, Gwen and

Edranol cultivars had the best general desirability and were well accepted by

the sensory evaluation panel. The rest of the cultivars maintained good general

desirability until 21 days of storage (table 4). In slices, during the storage

period, the fruit became softer and affected the general desirability. After 28

days of storage best quality product was obtained by the cultivars Gwen and

Edranol (table 5).

4. Discussion

The antioxidants used to

prevent browning did not affect significantly the taste avocado pulp nor slices

in all the cultivars treated.

The best gas combination to

store avocado pulp and slices were 80% N2

– 20% CO2 and 90% N2 - 10% CO2, also good quality products

were obtained at only 40% vacuum.

Gwen and Edranol cultivars

had the best general quality products after 35 days of cold storage period.

Also Hass cultivar had good quality until 28 days of storage, the rest of the

cultivars maintained their quality by 21 days of cold storage or less.

As a general conclusion, the

storage of avocado pulp or slices, at cold storage in low density polyethylene

bags using vacuum or modified atmosphere, as a Gamma IV product, was a good

processing method to preserve avocado pulp of proper cultivars and maturity

levels.

5 - References

Arpaia,

M. L., 1988. Atmósferas modificadas y atmósferas controladas para el

almacenamiento de productos fruticolas. Panorama Agroeconómico 5: 15-22.

Hatton, TT., and Campbell,

C.V. 1959. Evaluation of indices for Florida avocado maturity. Florida State

Horticulture Society 72: 349.

Olaeta, J.A. and Rojas C.

1987. Effect of cultivar and maturity on the quality of frozen avocado pulp.

South African Growers Association Yearbook 10: 163-164.

Olaeta, J., Undurraga, P.,

and Molfino, 1995. Behavior in Refrigerated Storage of Cririmoya (Annona

cherimolla Mill.) processed in two mediums and stored in plastic bags with

modified atmospheres. Harvest and Post Harvest Technologies for Fresh Fruits

and Vegetables. Proceeding. The Mexican Association of Agricultural Engineers

p.322-325.

Olaeta and Undurraga 1995.

Estimation of the Ripening Index in avocado (Persea americana Mill). Harvest and Post Harvest

Technologies for Fresh Fruits and Vegetables. Proceeding. The Mexican

Association of Agricultural Engineers. p421- 425.